How Do You Repair a Single Membrane Roof?

If you’ve noticed signs of damage on your flat or low-slope roof, you might be wondering if a single membrane roof repair or roof membrane repair is enough—or if you’re facing a full replacement.

Whether you manage commercial properties or own a home in a storm-prone area, knowing how these roofing systems are repaired can help you make smarter, more cost-effective decisions.

In this article, we’ll break down the most common causes of damage, how to identify repair-worthy issues, what the professional repair process looks like, and why working with a trusted contractor like RayPro matters. You’ll also get insight into repair costs, DIY risks, and what sets our service apart.

Here’s what we’ll cover:

- What Is a Single Membrane Roof?

- Common Causes of Damage to Single Membrane Roofs

- How to Tell If Your Single Membrane Roof Needs Repair

- How Professionals Repair a Single Membrane Roof (Step-by-Step)

- Why DIY Repairs Are Risky for Membrane Roofs

- How Much Does a Single Membrane Roof Repair Cost?

- Why Choose RayPro for Your Roof Repair Needs

- Conclusion: Don’t Wait Until Minor Damage Becomes a Major Cost

First, let’s understand what a single membrane roof actually is—and how to tell if that’s what you’re working with.

What Is a Single Membrane Roof?

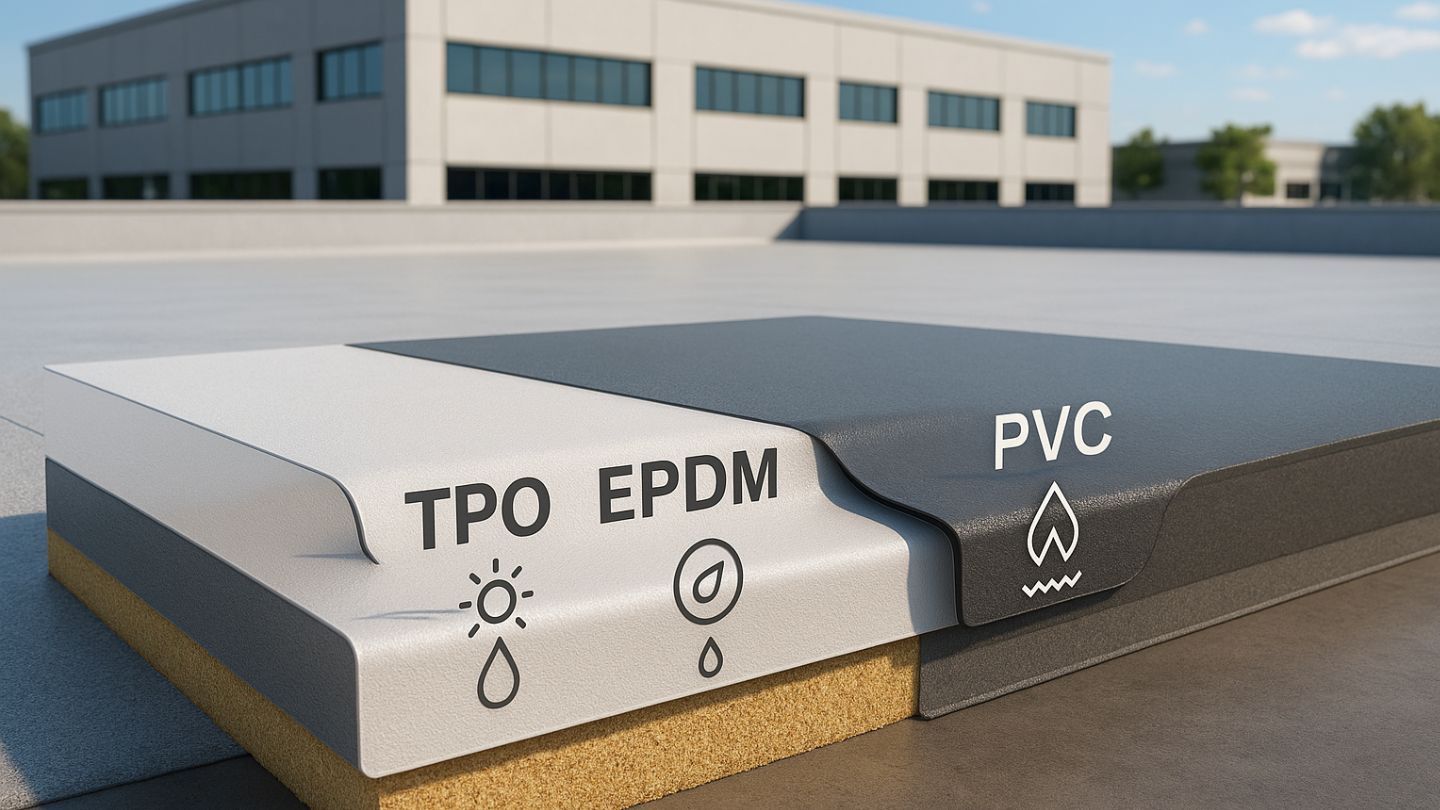

A single membrane roof—also known as a single-ply roofing system—is a type of flat or low-slope roof made from one continuous layer of synthetic material. It’s commonly used on commercial buildings, multi-family properties, warehouses, and even some residential homes in storm-prone or sun-exposed regions.

The most common types include TPO (Thermoplastic Olefin), EPDM (Ethylene Propylene Diene Monomer), and PVC (Polyvinyl Chloride). Each has its strengths, but all are designed to provide long-lasting protection from water, UV rays, and weather-related damage.

These systems use a flexible membrane for roof repairs and protection, which is mechanically fastened, adhered, or heat-welded into place to form a watertight barrier that’s both flexible and durable.

If you’re unfamiliar with the differences between materials, this guide on single-ply roofing materials offers a helpful comparison of TPO, PVC, and EPDM systems.

If your building has a smooth, rubber- or plastic-like surface, TPO roof repair services may be the right solution for addressing damage or leaks.

Key takeaway: A single membrane roof is a modern, efficient roofing system often found on commercial or flat-roofed buildings. Knowing what type you have helps ensure the right repair method is used when issues arise. Learn more about our Flat Roof Services for commercial and residential buildings.

Common Causes of Damage to Single Membrane Roofs

Even though single membrane roofs are built for durability, they’re still vulnerable to a variety of wear-and-tear factors—especially in climates like Florida’s or in high-traffic commercial settings. Understanding what can go wrong helps you stay ahead of potential issues and avoid costly repairs down the road.

Here are the most common reasons a single membrane roof repair may be needed:

- UV Exposure: Prolonged sun exposure can dry out and degrade membrane materials over time, causing cracks, brittleness, or shrinkage—especially in unshaded areas.

- Storm Damage (Wind & Hail): Severe storms can lift membrane edges, puncture surfaces, or tear seams. Hail strikes can create invisible damage that leads to leaks later.

- Aging & Weathering: Even well-installed systems naturally deteriorate over time. As membranes age, adhesives weaken and materials lose flexibility, making them more prone to cracks and leaks.

- Foot Traffic: Frequent rooftop access—common in commercial buildings with HVAC units—can wear down protective layers, cause punctures, or separate seams if walk pads aren’t in place.

- Poor Installation or Repairs: A subpar installation (or a rushed repair job) can lead to improper sealing, trapped moisture, or uneven surfaces—all of which shorten your roof’s lifespan.

To better understand these vulnerabilities, check out this practical overview on troubleshooting common issues with single-ply roofs, which includes real-world scenarios and warning signs.

Key takeaway: Many of the issues that lead to membrane roof failure are preventable with proper installation, routine inspections, and prompt attention after storms. Spotting these causes early is your best defense against major damage.

How to Tell If Your Single Membrane Roof Needs Repair

Even though single membrane roofs are known for their durability, they still require regular monitoring—especially after storms, high foot traffic, or years of exposure. Identifying early warning signs can help you avoid major structural issues and unexpected repair costs—especially when following a roof inspection checklist.

Here are the most common red flags that your membrane roof may need professional attention:

Leaks or Interior Stains

If you notice water spots on ceilings or walls, it could be a sign of a hidden puncture, open seam, or failed flashing. Even small issues may require single membrane roof leak repair, as they can quickly lead to insulation damage or mold growth if left untreated.

Bubbles or Blisters

Trapped moisture or air beneath the membrane creates raised, soft spots on the surface. These are more than cosmetic—they often signal underlying adhesion failure or vapor intrusion, especially common in aging or poorly installed roofs.

Torn Seams or Loose Flashing

The seams of your single-ply system are crucial to keeping the roof watertight. If they start to separate—or if flashing pulls away from edges, vents, or HVAC units—it leaves your building vulnerable to water intrusion.

Pooling Water or Membrane Wrinkles

Flat and low-slope roofs must drain properly. If you’re seeing water ponding in areas more than 48 hours after rain, or if the membrane looks distorted, it may indicate improper slope, clogged drains, or substrate deterioration.

Quick Roof Health Checklist

Use this quick self-assessment to decide whether it’s time to call a professional:

- Water stains inside the building

- Soft, raised blisters or bubbles on the membrane

- Visible tears, rips, or seam separation

- Loose or rusted flashing at edges or penetrations

- Pooling water more than 48 hours after rainfall

- Wrinkles or shifting in the roof membrane

- Mold or mildew smells in the attic or top floors

If you’ve checked any of the above, it’s a strong sign your roof needs attention. Don’t wait—book a Roof Safety Assessment to get a certified evaluation before the damage worsens.

How Professionals Repair a Single Membrane Roof (Step-by-Step)

When it comes to single-ply membrane roof repair and single ply roof repair, precision and expertise are non-negotiable. A rushed or poorly executed fix can lead to recurring leaks, energy loss, or even voided warranties. That’s why certified professionals—like the team at RayPro—follow a proven, step-by-step process to ensure long-lasting results.

Here’s how to repair a flat membrane roof—or properly repair roof membrane systems—using a standard single membrane repair process:

1. Inspection & Damage Assessment

A licensed roofing expert inspects the entire surface for visible and hidden issues, including punctures, seam separation, trapped moisture, and signs of aging. This step determines whether the roof can be repaired or if single membrane roof replacement options should be considered.

2. Surface Cleaning & Preparation

As part of the roof coating repair process, the damaged area is thoroughly cleaned and dried to remove debris, dirt, and any old adhesives. A clean surface ensures the repair materials bond properly and last longer.

3. Material Selection & Patch Prep

Depending on your roof type (TPO, EPDM, or PVC), the right patching materials are chosen. For example:

- TPO or PVC roofs typically use heat-welded patches for seamless sealing

- EPDM roofs may require specialized adhesives or tape-based solutions

4. Sealing or Heat-Welding the Patch

The repair is applied using adhesive or a hot-air welder (based on membrane type). Edges are sealed tightly to ensure the patch is fully watertight and integrated with the existing membrane.

5. Post-Repair Inspection

Once complete, the repair area is inspected again to confirm it’s secure, watertight, and up to code. The contractor may also test for leaks or moisture intrusion to ensure nothing was missed.

Pro Tip: The repair process may look simple on paper—but proper execution requires the right tools, material knowledge, and experience with flat or low-slope commercial roofs. That’s why relying on pros pays off in the long run.

Key takeaway: A professional single membrane roof repair isn’t just about patching a hole or simply patching roof membrane surfaces—it’s a careful, methodical process that ensures the fix holds up against weather, wear, and time.

Why DIY Repairs Are Risky for Membrane Roofs

If you’re handy or budget-conscious, tackling a DIY single-ply roof repair might seem like a quick fix—but when it comes to single membrane systems like TPO, EPDM, or PVC, that choice can end up costing far more in the long run.

The Risks of DIY Roof Repair

- Voided Warranties: Most membrane roofing materials come with manufacturer warranties that require certified installation and repair. A DIY patch job—even a small one—can void your coverage entirely.

- Improper Sealing: Single-ply systems rely on precise techniques like heat-welding or specialized adhesives. Without the right tools or experience, it’s easy to leave gaps that allow water infiltration or seam failure.

- Hidden Damage Goes Unnoticed: A surface-level patch might hide deeper issues like saturated insulation or sub-deck rot. Professionals know how to spot these before they escalate.

- Safety Hazards: Working on a roof without proper fall protection or equipment is dangerous. Even one misstep can lead to serious injury or liability issues—especially on commercial buildings.

Why Professional Help Pays Off

Hiring a certified contractor like RayPro means your roof gets evaluated and repaired the right way, using approved materials and techniques. You also gain peace of mind from strong warranties, safety compliance, and expert guidance on whether a repair is enough—or if a larger issue needs attention.

Key takeaway: DIY may save money upfront, but when it comes to single membrane roofs, it introduces serious risks—both to your property and your safety. Trusting a professional ensures your repair is code-compliant, watertight, and built to last.

How Much Does a Single Membrane Roof Repair Cost?

The cost of a single membrane roof repair can vary widely depending on several key factors. On average, most repairs fall between $500 and $3,500, but larger or more complex issues—especially on commercial properties—can range much higher.

Factors That Influence Repair Costs:

- Extent of Damage: A small seam tear or puncture will cost far less to fix than widespread membrane shrinkage or saturated insulation.

- Roof Size & Accessibility: Larger roofs or those with difficult access (like tall multi-story buildings) may require more labor and safety equipment.

- Material Type: TPO, EPDM, and PVC each require specific repair methods and tools—some more expensive than others.

- Labor & Location: Regional labor rates and code requirements (such as those in Florida) can also affect the final cost.

- Urgency: Emergency Roof Repair after a storm or major leak may carry premium pricing due to rapid response needs.

Get a Custom Quote—Not a Guess

Every roof is different, which is why a one-size-fits-all price isn’t realistic. At RayPro, we offer free inspections and detailed estimates so you know exactly what you’re paying for—before any work begins.

And if budget is a concern, we’ve got you covered. RayPro offers flexible financing options of up to $250,000 to make quality repairs more accessible without cutting corners.

Key takeaway: While minor repairs may be relatively affordable, the smartest way to understand your actual cost is through a professional quote.

With RayPro, you’ll get transparent pricing, expert recommendations, and the financing flexibility you need to protect your property without delay. Contact Us today to get started.

Ready for a quote? Schedule your free inspection today.

Why Choose RayPro for Your Roof Repair Needs

When it comes to repairing a single membrane roof, experience, trust, and professionalism matter. At RayPro Roofing & General Contracting, we bring over 17 years of hands-on expertise across 17 states, serving both commercial and residential clients with dependable, code-compliant roofing solutions.

Whether you’re managing a multi-family property, overseeing a retail facility, or protecting your home from Florida’s unpredictable weather, our team has the tools, training, and track record to deliver repairs that last.

What Sets RayPro Apart:

- Fully Licensed & Insured professionals who meet industry standards

- Comprehensive services for both commercial and residential properties

- Clear, upfront pricing—no hidden fees, no surprises

- Industry-leading warranties that give you long-term peace of mind

- End-to-end project management—from inspection to cleanup

From minor patch jobs to complex membrane system repairs, we tailor every solution to your specific needs and budget. And if cost is a concern, our financing options up to $250,000 make it easier than ever to move forward with confidence.

Schedule a free inspection today and see why thousands of clients trust RayPro to protect what matters most.

Conclusion: Don’t Wait Until Minor Damage Becomes a Major Cost

Single membrane roof systems are durable—but they’re not invincible. From UV exposure and storm damage to aging seams and hidden leaks, even small issues can lead to big repair bills if ignored.

That’s why knowing the signs of trouble, understanding how repairs are done, and acting quickly can save you time, stress, and money.

Whether you’re seeing bubbles on your TPO roof, a tear in your EPDM system, or water stains indoors, it’s always worth getting a professional opinion.

A certified contractor will not only diagnose the problem correctly but also ensure your repair is safe, sealed, and built to last.

At RayPro, we’re here to help with transparent pricing, expert guidance, and reliable repairs—backed by over 17 years of experience and a commitment to getting the job done right.

Let us walk your roof and give you a no-obligation quote. Schedule your free inspection today.

Frequently Asked Questions (FAQs)

The best way to patch a TPO roof is by using a heat-welded TPO patch, applied by a trained professional. This method ensures a watertight bond and maintains the integrity of the roofing system. Adhesives or tapes are not recommended for long-term fixes, especially in commercial settings.

Yes—many single membrane roofs can be repaired without needing full replacement, especially when a targeted single ply membrane repair is performed and the damage is localized and caught early. A professional inspection can determine whether patching, seam resealing, or targeted reinforcement is enough to restore the system’s performance.

A well-executed repair can last anywhere from 5 to 15 years, depending on the roofing material, the quality of the repair, and ongoing maintenance. Using the correct patching method and ensuring proper sealing are key to maximizing lifespan.

While it may be tempting, DIY repairs on commercial roofs are risky. Improper techniques can void warranties, compromise waterproofing, and miss hidden damage. It’s safer and more cost-effective to have certified professionals handle the job.

Immediately. Even a small puncture can allow moisture to seep into your building, leading to insulation damage, mold growth, or structural issues. Delaying repairs often turns a minor problem into a major—and more expensive—one.