How Long Do Standing Seam Metal Roofs Last?

If you’re wondering how long do standing seam metal roofs last, you’re not alone. Whether you own a commercial property or a residential home, understanding the lifespan of this durable, low-maintenance roofing system is essential—especially if you’re facing storm damage, aging infrastructure, or planning an upgrade.

In this article, we’ll cover the expected lifespan of standing seam metal roofs, what influences their durability, and how to extend their performance through proper care. You’ll also learn how to spot the signs that it may be time for a replacement and why this roofing system offers one of the best long-term investments on the market.

Here’s what we’ll cover:

- What Is a Standing Seam Metal Roof?

- Average Lifespan of Standing Seam Metal Roofs

- Factors That Impact Metal Roof Longevity

- Signs Your Standing Seam Roof May Need Replacement

- How to Maximize the Life of Your Standing Seam Roof

- Conclusion: Longevity That Pays Off

First, let’s take a closer look at what defines a standing seam metal roof.

What Is a Standing Seam Metal Roof?

Standing seam metal roofs are known for their strength, sleek appearance, and long-term durability—especially in areas prone to extreme weather, thanks to the benefits of standing seam metal roofs.

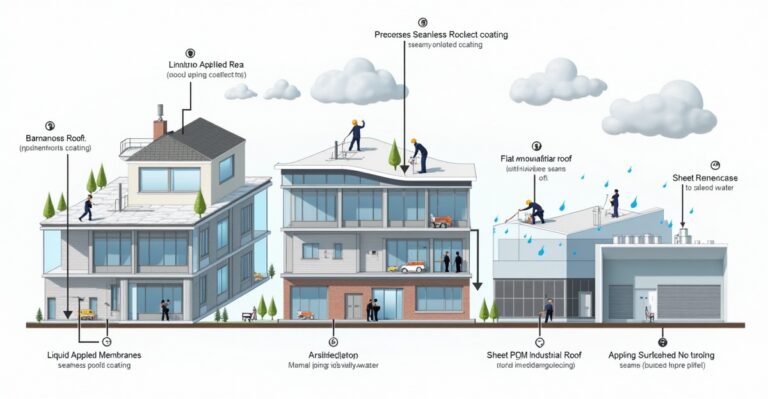

This type of roofing system features vertical metal panels that run from the ridge to the eave, with raised seams (or “legs”) that interlock above the flat surface of the roof.

These seams not only create a distinctive look but also serve a crucial function: they conceal the fasteners and create a watertight barrier that stands up well to rain, wind, and temperature shifts.

Unlike exposed fastener systems, where screws penetrate the roofing panels and are vulnerable to loosening over time, standing seam systems hide all fasteners beneath the seams or clips.

This clean, low-profile design helps reduce the risk of leaks and minimizes ongoing maintenance—making it a smart choice for property owners looking for a long-term roofing investment.

If you’re new to the concept, this overview on the basics of standing seam metal roofs from The Spruce offers a great introduction to design types, applications, and material pros and cons.

Key Features and Benefits

- Durability: Standing seam panels are typically made from high-quality metals like steel, aluminum, or Galvalume and can last 40–70 years or more when properly installed.

- Weather Resistance: The concealed fasteners and interlocking seams make these roofs especially resistant to wind uplift, rain intrusion, and even hail—ideal for hurricane-prone states like Florida.

- Low Maintenance: With no exposed screws to back out or corrode, there’s less need for frequent upkeep compared to traditional asphalt or metal panel systems.

- Energy Efficiency: Most standing seam roofs can be coated with reflective finishes that help reduce heat absorption, supporting more efficient indoor cooling in warm climates.

- Modern Aesthetic: Their clean lines and bold appearance are popular with both contemporary home designs and commercial architecture.

Where They’re Commonly Used (Homes, Commercial, Industrial)

Standing seam metal roofs are incredibly versatile. While traditionally used on commercial buildings and industrial facilities, they’ve become increasingly popular for residential roof installation, especially in coastal or high-wind regions. Multi-family properties, office parks, and retail centers also benefit from their durability and minimal disruption during maintenance.

In Florida and other storm-prone states, standing seam roofs are often chosen for their superior performance in extreme weather conditions. They’re designed to handle wind gusts, driving rain, and salt-laden air—factors that can significantly shorten the lifespan of less resilient roofing systems.

Key takeaway: Standing seam metal roofs offer a premium blend of durability, efficiency, and weather resistance—making them a long-term roofing solution for both residential and commercial properties, particularly in challenging climates.

Average Lifespan of Standing Seam Metal Roofs

One of the biggest advantages of standing seam metal roofs is the lifespan of standing seam metal roofs, which is impressively long.

When properly installed and maintained, the standing seam metal roof lifespan can exceed that of traditional shingles by decades or flat membrane roofs—making them a smart investment for both residential and commercial properties.

Typical Lifespan Range (40–70 Years)

The standing seam metal roof life expectancy typically ranges from 40 to 70 years, depending on materials, installation quality, and regional weather conditions, depending on the materials used, the quality of the installation, and the local climate. In some cases, If you’re wondering how long does standing seam roof last, the answer could be over 70 years—especially with premium coatings and consistent care.

For broader insights into long-term roofing performance, including case studies and research, check out these metal roofing longevity statistics from the Metal Roofing Alliance.

Here’s a breakdown of typical lifespan ranges by material type based on the lifespan of metal roofs by material:

| Material | Expected Lifespan | Best Use Case |

| Aluminum | 40–50 years | Coastal homes or buildings (resistant to salt corrosion) |

| Steel (Galvanized) | 50–65 years | Inland commercial and residential properties |

| Galvalume | 60–70 years | High-humidity or storm-prone environments |

These estimates assume proper installation, regular inspections, and prompt repairs when needed. The choice of material should align with your location, climate risks, and long-term property goals.

How Warranties Compare to Real-World Performance

It’s important to understand that roof warranties often cover less than the roof’s actual performance potential. The typical standing seam metal roof warranty ranges from 20 to 40 years, covering defects in coating or material based on the manufacturer, depending on the finish and substrate. However, that doesn’t mean your roof will fail once the warranty expires.

In practice, well-maintained standing seam roofs often outlast their warranties by 10–30 years or more. Think of the warranty as protection against premature defects—not a reflection of maximum lifespan.

That said, some warranties may be voided by improper installation, lack of maintenance, or unapproved alterations. That’s why it’s essential to work with a certified, fully insured roofing contractor like RayPro Roofing & General Contracting, who follows manufacturer guidelines and offers additional workmanship warranties.

Key takeaway: The lifespan of standing seam metal roofs typically ranges from 40 to 70+ years when properly installed and maintained. While warranties may only cover part of that period, real-world performance often exceeds expectations—especially when backed by expert installation and regular upkeep.

Factors That Impact Metal Roof Longevity

While standing seam metal roofs are built for long-term performance, their actual lifespan depends on more than just the material. A range of environmental, structural, and workmanship factors can either extend or reduce the life of your roof.

Understanding these variables helps you get the most value from your roofing investment—whether you’re a homeowner or managing a multi-property portfolio.

Installation Quality

The most durable roofing system in the world can still fail prematurely if it’s installed poorly. Installation quality is one of the most critical factors influencing how long your standing seam metal roof will last.

A qualified, experienced roofing contractor will ensure:

- Proper seam alignment and fastening techniques

- Correct use of underlayment and roof insulation

- Secure roof flashing installation to prevent water intrusion

- Compliance with building codes and manufacturer guidelines

At RayPro, we’ve seen firsthand how poor workmanship leads to fastener failure, seam leaks, and costly repairs—especially in storm-prone regions. That’s why every RayPro project is completed by certified professionals trained in both residential and commercial roofing systems.

Maintenance Frequency and Upkeep

Many homeowners ask, do standing seam metal roofs require much maintenance? The answer is no—these systems are relatively low-maintenance compared to other roof types, but “low maintenance” doesn’t mean “no maintenance.” Without routine inspections and minor repairs, even a high-quality metal roof can deteriorate early.

To maximize roof longevity:

- Schedule annual inspections to check for fastener movement, panel shifting, or flashing wear

- Remove debris and standing water after major storms or seasonal changes

- Touch up scratched or faded finishes to prevent corrosion

- Clean gutters and downspouts to prevent water backup at the roof edge

Sticking to a consistent roof maintenance schedule can easily add 10+ years to your system’s life.

Climate and Environmental Stress

Florida and other coastal states present unique environmental challenges that can accelerate wear on any roofing system. Standing seam metal roofs are more resilient than most, but they’re still subject to:

- High winds and hurricanes: Uplift pressure can compromise improperly secured seams

- Salt-laden air: In coastal zones, salt accelerates corrosion—especially on uncoated steel

- Heavy rainfall and humidity: Moisture buildup increases the risk of rust and hidden leaks

- Hail and debris impact: Dents or punctures may compromise protective coatings over time

When wind or storm activity does cause damage, wind damage repair services may be necessary to prevent long-term issues.

That’s why selecting the right metal type and finish—and partnering with a roofing contractor who understands your region—is key to long-term roof performance.

Roof Design Considerations (Slope, Drainage, Insulation)

Your roof’s structure also plays a major role in its durability. Even the best metal roofing system can underperform if it’s installed on a poorly designed structure.

Important design factors include:

- Slope/Pitch: A steep slope promotes drainage and helps prevent standing water—especially critical in areas with heavy rainfall.

- Roof Drainage Solutions: Properly designed gutters, downspouts, and scuppers reduce the risk of water damage along seams and edges.

- Ventilation and Insulation: Adequate airflow in the attic or ceiling space prevents condensation, which can degrade fasteners and materials over time.

- Flashing and Transitions: Complex rooflines with valleys or dormers require expert flashing installation to avoid weak points.

Key takeaway: The longevity of your standing seam metal roof depends not only on the material but also on expert installation, proactive maintenance, smart design, and a roof system that’s built to handle your specific climate. Choosing a contractor like RayPro—experienced in managing roofing systems across 17 diverse states—can make all the difference in long-term performance.

Signs Your Standing Seam Roof May Need Replacement

Even the most durable roofing systems eventually show signs of wear. While standing seam metal roofs are known for their longevity, that doesn’t mean they’re immune to damage—especially after decades of exposure to harsh weather or inadequate maintenance. Identifying early signs of standing seam roof damage—such as leaks, rust, or seam separation—is critical to extending the roof’s lifespan—is critical to avoiding costly structural repairs and protecting your property long-term.

If you’re not sure whether it’s time to repair or replace your standing seam roof, start with these telltale signs.

Leaks, Corrosion, or Rust

Water infiltration is one of the clearest indicators that your roof is no longer performing as it should. Because standing seam systems conceal fasteners, leaks are often the result of:

- Worn or improperly sealed flashing

- Compromised seams or joints

- Rust developing under the paint or coating

If you’re noticing leaks, roof leak detection can help identify the source before damage spreads.

Corrosion may start small but can spread rapidly—especially in humid or coastal environments like Florida. Once rust penetrates through the metal panel, replacement is often more cost-effective than patching.

What to look for:

- Water stains on ceilings or walls

- Discoloration or bubbling paint on metal panels

- Flaking or powdery rust spots around seams or edges

Panel Distortion or Movement

Over time, metal panels may expand and contract due to temperature changes. If the roof was not installed with proper spacing or floating clip systems, this thermal movement can lead to:

- Buckling or oil-canning (visible wavy distortion in the panels)

- Shifted or lifted seams that no longer form a tight seal

- Panel separation, especially at ridge caps or valley transitions

These issues aren’t just cosmetic—they can lead to water intrusion and reduced wind resistance. Left unaddressed, warped panels can compromise the overall integrity of your roofing system.

Failing Fasteners or Flashings

While standing seam roofs don’t rely on exposed fasteners, they still require secure clips and hidden fastening systems to keep panels in place. Over time, these components can loosen, corrode, or detach—especially if exposed to vibration from HVAC units or storm activity.

Likewise, flashing (the metal used to seal edges, penetrations, and roof transitions) may crack, lift, or wear down, creating openings for water and debris.

Warning signs include:

- Rattling sounds in wind

- Loose or detached flashing around vents or skylights

- Fasteners pulling through the panel or visible along seams

Flashing may crack, lift, or deteriorate—creating opportunities for leaks. If repairs aren’t made in time, you may need roof flashing repair.

Roof Health Checklist

Use this quick visual checklist to help determine if your standing seam metal roof may be nearing the end of its service life:

- Water stains indoors or signs of roof leaks

- Visible rust, corrosion, or paint deterioration

- Distorted panels or uneven seams

- Loose flashing or signs of sealant failure

- Noise in high winds or during temperature shifts

- Age of roof exceeds 40+ years without recent inspection

Key takeaway: If you notice any of these issues—or if your roof hasn’t been professionally inspected in years—it may be time to consider a roof refurbishment. Addressing damage early often leads to simpler repairs, but waiting too long could mean higher costs and greater risks. A no-obligation roof inspection from RayPro can help you make the right call with confidence.

How to Maximize the Life of Your Standing Seam Roof

Standing seam roof maintenance and longevity go hand-in-hand—these roofs are designed to go the distance, but they need care to perform at their best over time. Whether you’re maintaining a single-family home or a portfolio of commercial properties, a proactive approach can help you stretch your roof’s lifespan well beyond the average.

Here’s how to get the most from your roofing investment.

Preventive Maintenance Best Practices

Routine maintenance doesn’t just preserve the look of your roof—it protects its structural integrity and weatherproofing capabilities. The good news? Standing seam systems require less upkeep than traditional roofs. The key is consistency.

Best practices include:

- Remove debris (leaves, branches, dirt) from the roof surface and valleys

- Clear gutters and downspouts to prevent water back-up, emphasizing the importance of how gutters protect your roof and property.

- Check for scratches, fading, or coating wear and touch up as needed

- Trim overhanging branches to reduce impact damage during storms

- Document minor issues and monitor changes over time

Pro Tip: Schedule your basic maintenance twice per year—once in spring (after winter weather) and once in fall (before storm season hits).

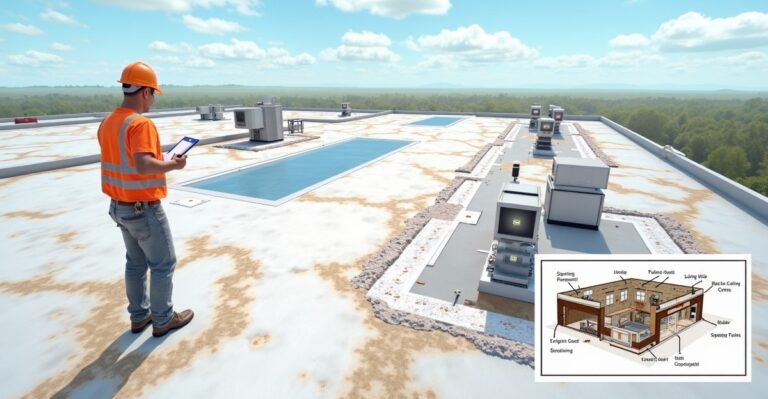

Annual Inspections and When to Call a Pro

While some upkeep can be handled in-house, a licensed roofing contractor should inspect your system at least once a year—or immediately after a severe storm. Annual inspections are especially important for properties in high-risk climates like Florida, where hail, wind, and salt exposure accelerate wear.

After severe storms or annually, schedule a roof safety assessment to catch hidden problems early.

A professional inspection typically includes:

- Evaluating panel seams and connections

- Checking hidden fasteners, clips, and sealants

- Assessing flashing around vents, chimneys, skylights, and transitions

- Looking for subtle signs of corrosion, movement, or water intrusion

- Confirming that ventilation and drainage systems are functioning properly

After severe storms or annually, schedule a roof safety assessment to catch hidden problems early.

Minor Repairs That Can Prevent Major Issues

Examples of smart early interventions include:

- Resealing flashing

- Replacing clips or brackets

- Recoating metal to prevent corrosion

- Refastening shifted panels

- Replacing cracked sealant

For serious issues after storms or emergencies, emergency roof repair may be the best route.

Maintenance Calendar Suggestion:

- Spring: Inspect for winter damage; clear debris

- Fall: Prep for storm season; check drainage and fasteners

- After major storms: Request a rapid inspection to catch hidden damage early

RayPro offers full-service maintenance and inspection packages, making it easy to stay ahead of issues without adding more to your plate. Our team documents each visit, flags potential concerns, and offers honest, cost-effective recommendations.

Minor Repairs That Can Prevent Major Issues

Catching and addressing small problems early is the best way to prevent expensive surprises down the line. A lifted seam, minor flashing damage, or loose fastener may seem small—but left unchecked, it can lead to leaks, rust, or structural failure.

Examples of small fixes that make a big difference:

- Resealing worn flashing around roof penetrations

- Replacing a single corroded clip or bracket

- Touching up protective coatings before rust sets in

- Refastening shifted panels or re-securing transitions

- Replacing cracked sealant along ridge caps or valleys

These types of quick repairs are far less expensive than a full roof replacement—and help keep your roofing system under warranty.

Key takeaway: A little routine attention goes a long way. With preventive maintenance, annual inspections, and timely repairs, your standing seam metal roof can exceed 70 years of high performance. RayPro’s experienced team is here to support that journey with honest insights, full-service care, and roofing solutions built to last.

Conclusion: Longevity That Pays Off

Standing seam metal roofs aren’t just built to last—they’re built to deliver long-term value. With a typical lifespan of 40 to 70+ years, these systems offer unmatched durability, low maintenance demands, and reliable performance in even the harshest climates.

That makes them a smart investment for homeowners and property managers who want peace of mind and a strong return on their roofing dollars.

But longevity isn’t automatic. The true life of your standing seam roof depends on three critical factors: quality installation, routine maintenance, and regional climate conditions. Choosing the right materials is important—but partnering with a reliable contractor who understands your property’s unique needs is what ensures you get the most out of your investment.

Not sure how much life your roof has left? Contact Us to schedule a no-pressure inspection with RayPro and get the answers you need—honest, professional, and built around your goals.

Frequently Asked Questions

In Florida’s hot, humid, and storm-prone climate, a standing seam metal roof typically lasts 40 to 60 years, though with proper maintenance and high-quality materials like Galvalume or aluminum, it can exceed 70 years. Choosing corrosion-resistant coatings and scheduling annual inspections can help offset damage from salt air, UV exposure, and hurricanes.

Standing seam metal roofs require minimal but consistent maintenance. Key tasks include:

Clearing debris and cleaning gutters

Checking for loose fasteners or flashing

Inspecting for signs of corrosion or panel movement

Resealing or recoating areas as needed

Annual professional inspections and post-storm checkups are also recommended, especially in regions like the Southeast—part of a proper standing seam metal roof inspection schedule.

Yes—significantly longer. While asphalt shingles typically last 15 to 25 years, a standing seam metal roof can last 40 to 70+ years. Metal roofs also hold up better against wind, hail, and UV damage, making them a more durable and cost-effective option over the long term.

Several factors can reduce the life of a standing seam roof, including:

Poor installation practices

Lack of maintenance or inspection

Exposure to salt air and extreme weather

Blocked drainage systems

Incompatible materials causing galvanic corrosion

Proactive care and using a certified roofing contractor can prevent most of these issues.

Yes, individual panels can be replaced, but it requires precision. Because panels interlock, removal and replacement should be done by a professional to avoid damaging adjacent sections or compromising the waterproof seal. This is why early intervention and minor repairs are always preferable to emergency replacements.